Fixings and Fastenings

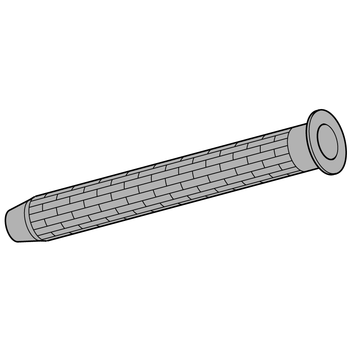

Perforated Sleeve SH

Application

Perforated sleeve to be used in perforated brick in combination with Anchor Rods VMU. The version VM-SH is equipped with a convenient arrester clack, avoiding a slipping into the drill hole.

For larger anchoring depths, the metal sleeves VMU-SH are available.

Installation

| 1. | Drill hole and blow out/brush. |

| 2. | Flush insert Perforated Sleeve into drill hole. In case of several drill holes, prepare all dowel drills in order to avoid interruptions during injection of the adhesive. The Perforated Sleeve will be filled almost completely with the injection adhesive. |

| 3. | Insert Anchor Rod with spiral, rotating movement. The adhesive being displaced by the Anchor Rod escapes through the perforation and effectuates an adhesion of the system in the hollow spaces of the wall during hardening process. The hardened injection adhesive gives a secure fastening to the base material. |

Technical Data

Maximum usable length tfix [mm] for the application in solid or perforated brick

| VM-SH 12 x 80 | VM-SH 16 x 85 | VM-SH 16 x 130 | VM-SH 20 x 85 | VM-SH 20 x 130 | |

|---|---|---|---|---|---|

| VMU-A 8-20/110 | 20 | 15 | - | - | - |

| VMU-A 8-55/145 | 55 | 50 | 5 | - | - |

| VMU-A 10-30/130 | - | 35 | - | - | - |

| VMU-A 10-50/150 | - | 55 | 10 | - | - |

| VMU-A 12-15/120 | - | - | - | 20 | - |

| VMU-A 12-50/155 | - | - | - | 55 | 10 |

| VMU-A 16-15/160 | - | - | - | 55 | 10 |

| Material: | Plastic (polypropylene) |

| Material sold by the metre: | Metal |

1) Delivery date on request - goods are procured on an order-related basis.